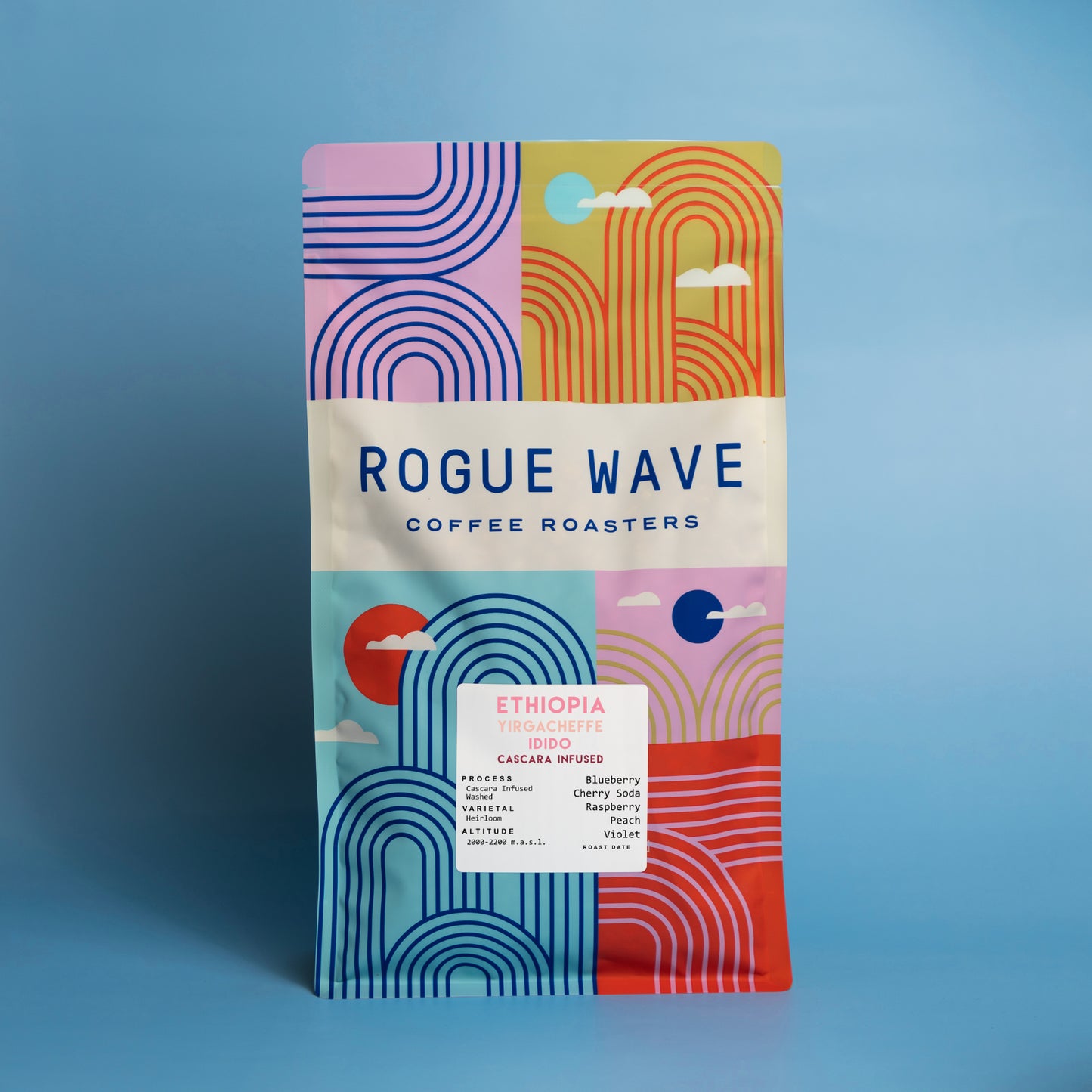

This Cascara-infused process begins with the typical purchasing of ripe cherries from smallholder growers, who deliver them to the washing station. An additional premium is paid for cherries to undergo flotation in float tanks, where lower-density cherries are skimmed off. This leaves behind the highest density fruit, which is then scooped out and carried to drying tables. Here, the cherries are meticulously hand-sorted to identify and remove any visible defects.

At this stage, the bright red cherries are deposited into large cement hoppers connected to the pulping machine. The seeds are subsequently channeled into various density channels and tanks, initiating fermentation to loosen the sticky mucilage surrounding the seed. This is where the innovative Cascara-Infused process begins, which introduces transformative elements to the traditional method.

This process involves not only filling the fermentation tank with pulped parchment and covering it with water in the standard way but also adding cascara from previously dried natural processed lots. The fruity cascara enhances the flavor of the fermenting coffee beans, allowing them to interact for a controlled cycle. Once fermentation is complete, the parchment coffee is guided into washing channels where local filtered river water flows over them. Laborers, often singing songs to stay synchronized, scrub the beans with wooden rakes until the water runs clear. After washing, the parchment is transferred to wood-and-wire trays for draining, allowing them to drip-dry for 6-10 hours. Following the draining process, the beans, still in their parchment jackets, are carefully spread on shaded open air drying tables to reduce moisture under the sun.

Once dried to the desired level, the coffee is transported first to a regional processing mill, then to Addis Ababa, the capital city, for final export processing. From there, they are loaded into containers for the next stage of their journey from tree to cup.

Mikiyas Bogale inherited a washing station from his father in 2020, and works with producers in the Idido area. The area produces about 300 bags of coffee per year